Sharaxaada

Si aad u soo saarto alaab tayo sare leh oo qiimo jaban leh oo leh waxtarka ugu sarreeya iyo isku halaynta, waa inaad doorataa qaybo xidhashada kuwaas oo loogu talagalay codsigaaga burburinta gaarka ah. Qodobbada ugu muhiimsan ee ay tahay in la tixgeliyo sida soo socota:

1. Nooca dhagaxa ama macdanta la burburiyo.

2. Cabbirka walxaha walxaha, nuxurka qoyaanka iyo heerka adkaanta Mohs.

3. Qalabka iyo nolosha baararka dharbaaxada ee hore loo isticmaalay.

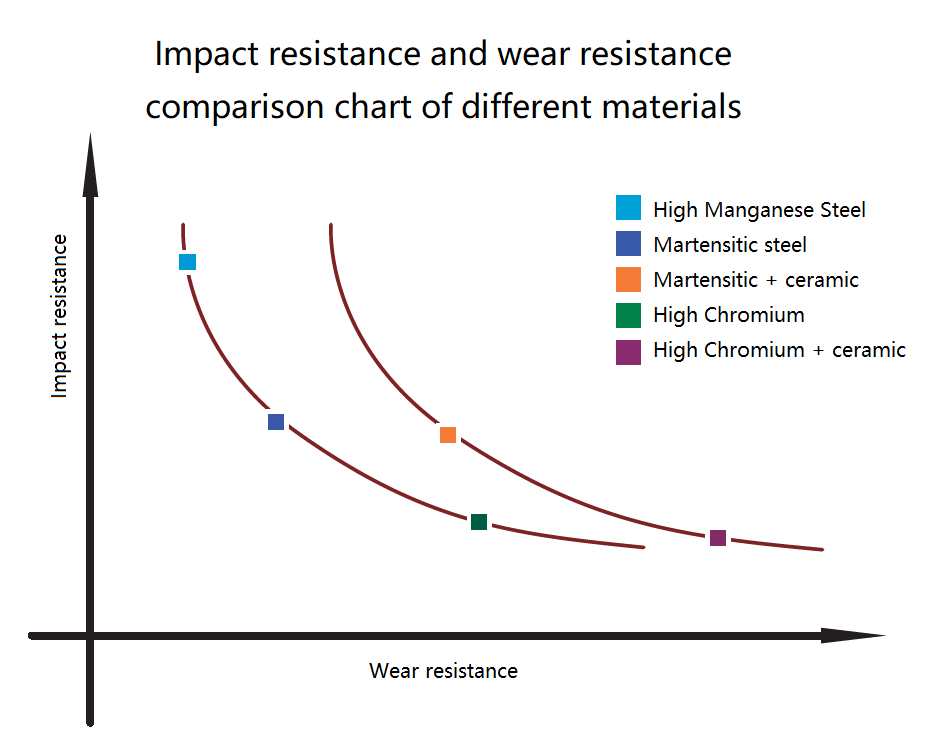

Guud ahaan, xidhashada caabbinta (ama adkaanta) ee gidaarada ku rakiban biraha u adkaysta waxay si lama filaan ah u dhimi doontaa iska caabbinta (ama adkaanta). Habka dhejinta dhoobada ee walxaha matrixka birta ayaa si weyn u kordhin kara caabbinta xirashada iyada oo aan saameyn ku yeelanayn iska caabbinta saameynta.

Birta Manganese Sare

Birta manganese-ka sare waa walax u adkaysata xidhashada oo leh taariikh dheer waxaana si weyn loogu isticmaalay burburinta saamaynta. Birta manganese sare waxay leedahay iska caabin aad u wanaagsan. Iska caabbinta xirashadu waxay badanaa la xiriirtaa cadaadiska iyo saameynta dusha sare. Marka saameyn weyn la adeegsado, qaabka austenite ee dusha sare waa lagu adkeyn karaa HRC50 ama ka sareeya.

Dubeyaal saxan bir manganese sare waxaa guud ahaan kaliya lagu talinayaa in lagu burburiyo aasaasiga ah oo leh walxo cabbirka qayb feed weyn iyo engegnaanta hoose.

Halabuurka kiimikada ee birta manganese sare

| Qalab | Halabuurka Kiimikada | Hantida Mashiinka | ||||

| Mn% | Cr% | C% | Si% | Ak/cm | HB | |

| Mn14 | 12-14 | 1.7-2.2 | 1.15-1.25 | 0.3-0.6 | > 140 | 180-220 |

| Mn15 | 14-16 | 1.7-2.2 | 1.15-1.30 | 0.3-0.6 | > 140 | 180-220 |

| Mn18 | 16-19 | 1.8-2.5 | 1.15-1.30 | 0.3-0.8 | > 140 | 190-240 |

| Mn22 | 20-22 | 1.8-2.5 | 1.10-1.40 | 0.3-0.8 | > 140 | 190-240 |

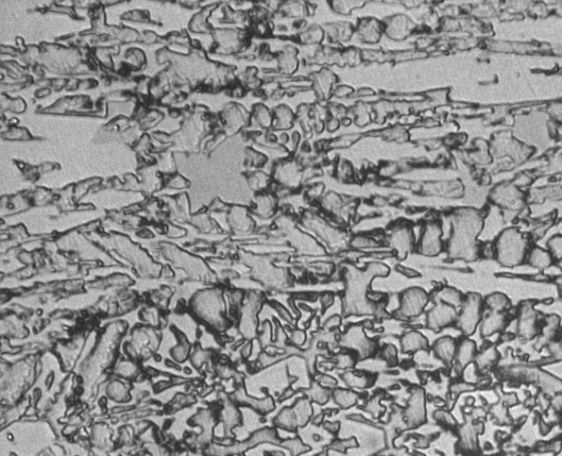

Qaab-dhismeedka yar ee birta manganese sare

Birta Martensitic

Qaab dhismeedka Martensite waxaa lagu sameeyay qaboojin degdeg ah oo birta kaarboonka ah si buuxda loo qaboojiyey. Atomyada kaarboonku waxay ku faafi karaan martensite kaliya habka qaboojinta degdega ah ka dib daaweynta kulaylka. Birta Martensitic waxay leedahay adayg ka sarreeya birta-manganese-ka sare, laakiin iska caabbinta saameynteeda si isku mid ah ayaa loo dhimay. Adkeega birta martensitic waxay u dhaxaysaa HRC46-56. Iyada oo ku saleysan guryahan, birta dharbaaxada martensitic ayaa guud ahaan lagula talinayaa in la burburiyo codsiyada halka saameyntu aad u yar tahay laakiin caabbinta xirashada sare loo baahan yahay.

Qaab-dhismeedka yar ee birta martensitic

Birta cad ee Chromium sare

Birta cad ee chromium sare, kaarboon waxa lagu daraa chromium oo ah qaab karbiide chromium ah. Birta cad ee chromium sare waxay leedahay iska caabin aad u wanaagsan. Daaweynta kulaylka ka dib, engegnaanteedu waxay gaari kartaa 60-64HRC, laakiin iska caabbinta saameynteeda si isku mid ah ayaa loo dhimay. Marka la barbar dhigo birta manganese-ka sare iyo birta martensitic, birta chromium-ka sare waxay leedahay iska caabbinta xidhashada ugu sareysa, laakiin iska caabinteeda ayaa sidoo kale ah tan ugu hooseysa.

Birta cad ee chromium sare, kaarboon waxa lagu daraa chromium oo ah qaab karbiide chromium ah. Birta cad ee chromium sare waxay leedahay iska caabin aad u wanaagsan. Daaweynta kulaylka ka dib, engegnaanteedu waxay gaari kartaa 60-64HRC, laakiin iska caabbinta saameynteeda si isku mid ah ayaa loo dhimay. Marka la barbar dhigo birta manganese-ka sare iyo birta martensitic, birta chromium-ka sare waxay leedahay iska caabbinta xidhashada ugu sareysa, laakiin iska caabinteeda ayaa sidoo kale ah tan ugu hooseysa.

Halabuurka kiimikada ee birta cad ee chromium sare

| ASTM A532 | Sharaxaada | C | Mn | Si | Ni | Cr | Mo | |

| I | A | Ni-Cr-Hc | 2.8-3.6 | 2.0 ugu badnaan | 0.8 ugu badnaan | 3.3-5.0 | 1.4-4.0 | 1.0 ugu badnaan |

| I | B | Ni-Cr-Lc | 2.4-3.0 | 2.0 ugu badnaan | 0.8 ugu badnaan | 3.3-5.0 | 1.4-4.0 | 1.0 ugu badnaan |

| I | C | Ni-Cr-GB | 2.5-3.7 | 2.0 ugu badnaan | 0.8 ugu badnaan | 4.0 ugu badnaan | 1.0-2.5 | 1.0 ugu badnaan |

| I | D | Ni-HiCr | 2.5-3.6 | 2.0 ugu badnaan | 2.0 ugu badnaan | 4.5-7.0 | 7.0-11.0 | 1.5 ugu badnaan |

| II | A | 12Cr | 2.0-3.3 | 2.0 ugu badnaan | 1.5 ugu badnaan | 0.40-0.60 | 11.0-14.0 | 3.0 ugu badnaan |

| II | B | 15CrMo | 2.0-3.3 | 2.0 ugu badnaan | 1.5 ugu badnaan | 0.80-1.20 | 14.0-18.0 | 3.0 ugu badnaan |

| II | D | 20CrMo | 2.8-3.3 | 2.0 ugu badnaan | 1.0-2.2 | 0.80-1.20 | 18.0-23.0 | 3.0 ugu badnaan |

| III | A | 25Cr | 2.8-3.3 | 2.0 ugu badnaan | 1.5 ugu badnaan | 0.40-0.60 | 23.0-30.0 | 3.0 ugu badnaan |

Qaab-dhismeedka-yar ee Birta Cad ee Chromium Sare

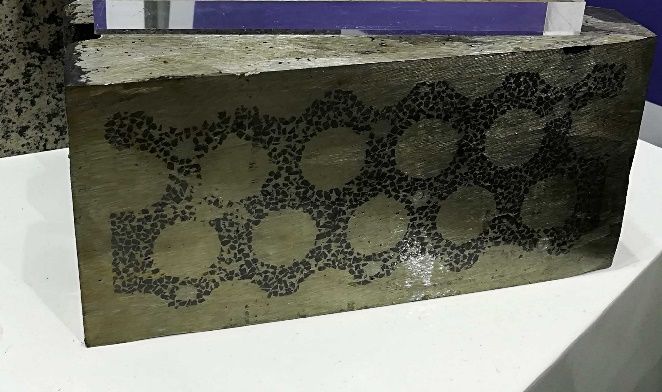

Maaddada dhoobada-Birta ah ee isku dhafan (CMC)

CMC waa shay u adkaysta xidhashada oo isku daraysa adkaanta wanaagsan ee walxaha macdanaha ah ( birta martensitic ama birta chromium-ka sare ah) oo ay weheliso adkaanta aadka u saraysa ee dhoobada warshadaha. Qaybaha dhoobada ee cabbir gaar ah ayaa si gaar ah loogu daaweeyaa si ay u sameeyaan jidh daloola oo ah qurubyo dhoobo ah. Birta dhalaalaysa waxay si buuxda u gashaa is dhex galka qaab dhismeedka dhoobada inta lagu jiro tuurista waxayna si fiican isugu daraa qaybaha dhoobada.

Naqshadani waxay si wax ku ool ah u wanaajin kartaa waxqabadka ka-hortagga xirashada ee wejiga shaqada; Isla mar ahaantaana, jidhka ugu weyn ee birta dharbaaxada ama dubbaha ayaa weli ka samaysan bir si loo hubiyo hawlgalkeeda badbaadada leh, si wax ku ool ah u xalliya khilaafka u dhexeeya xirashada caabbinta iyo iska caabinta saameynta, waxaana lagu hagaajin karaa xaalad shaqo oo kala duwan. Waxay u furaysaa goob cusub oo loogu talagalay xulashada qalabka dharka-sare ee inta badan isticmaalayaasha, waxayna abuurtaa faa'iidooyin dhaqaale oo wanaagsan.

a. Birta Martensitic + Ceramic

Marka la barbar dhigo birta dharbaaxada martensitic ee caadiga ah, dubbaha dharbaaxada dhoobada martensitic ayaa leh adayg sare oo ku yaal dusha sare ee dharbaaxada, laakiin caabbinta saameynta dubbaha dharbaaxada ma yarayn doonto. Xaaladaha shaqada, barkada dharbaaxada dhoobada ee martensitic waxay noqon kartaa bedel wanaagsan ee codsiga waxayna badanaa heli kartaa ku dhawaad 2 jeer ama nolol adeeg ka badan.

b. Birta cad ee Chromium Sare + Ceramic

Inkasta oo birta sare ee chromium-ka caadiga ah ay hore u leedahay iska caabin sare oo dharbaaxo ah, marka la burburinayo walxaha adag ee aadka u sarreeya, sida granite, baararka dharbaaxada adkaysiga badan ayaa badanaa loo isticmaalaa si ay u kordhiyaan noloshooda shaqada. Xaaladdan oo kale, birta kabka ah ee chromium-sare leh oo la geliyey bar dhoobo dhoobo ah ayaa xal fiican ah. Iyada oo ay ugu wacan tahay isku-xidhka dhoobada, qallafsanaanta dharka dusha sare ee dubbaha dharbaaxada ayaa sii kordhaysa, iyo caabbinta xirashada si weyn ayaa loo wanaajiyay, badanaa 2 jeer ama ka badan nolosha adeegga birta chromium ee caadiga ah.

Faa'iidooyinka Sheramic-Metal Composite Material (CMC)

(1) Adag laakiin aan jilicsanayn, adag oo xidhashada u adkaysta, gaaritaanka dheelitirnaanta labbada ee caabbinta xidhashada iyo adkaanta sare;

(2) Qallafsanaanta dhoobada waa 2100HV, iyo caabbinta xirashada waxay gaari kartaa 3 ilaa 4 jeer oo ka mid ah alaabta daawaha caadiga ah;

(3) Nakhshad qaabaysan oo shakhsi ah, khad xidhasho oo macquul ah;

(4) Cimri dheer oo adeeg iyo faa'iidooyin dhaqaale oo sarreeya.

Qiyaasta Alaabta

| Nooca mashiinka | Qaabka mashiinka |

| Metso | LT-NP 1007 |

| LT-NP 1110 | |

| LT-NP 1213 | |

| LT-NP 1315/1415 | |

| LT-NP 1520/1620 | |

| Hazemag | 1022 HAZ791-2 HAZ879 HAZ790 HAZ893 HAZ975 HAZ817 |

| 1313 HAZ796 HAZ857 HAZ832 HAZ879 HAZ764 HAZ1073 | |

| 1320 HAZ1025 HAZ804 HAZ789 HAZ878 HAZ800A HAZ1077 | |

| 1515 HAZ814 HAZ868 HAZ1085 HAZ866 HAZ850 HAZ804 | |

| 791 HAZ565 HAZ667 HAZ1023 HAZ811 HAZ793 HAZ1096 | |

| 789 HAZ815 HAZ814 HAZ764 HAZ810 HAZ797 HAZ1022 | |

| Sandvik | QI341 (QI240) |

| QI441(QI440) | |

| QI340 (I-C13) | |

| CI124 | |

| CI224 | |

| Kleemann | MR110 EVO |

| MR130 EVO | |

| MR100Z | |

| MR122Z | |

| Terex Pegson | XH250 (CR004-012-001) |

| XH320-cusub | |

| XH320 jir | |

| 1412 (XH500) | |

| 428 Tracpactor 4242 (300 sare) | |

| Shaashada korontada | Trackpactor 320 |

| Terex Finlay | I-100 |

| I-110 | |

| I-120 | |

| I-130 | |

| I-140 | |

| Rubblemaster | RM60 |

| RM70 | |

| RM80 | |

| RM100 | |

| RM120 | |

| Tesab | RK-623 |

| RK-1012 | |

| Extec | C13 |

| Telsmith | 6060 |

| Keestrack | R3 |

| R5 | |

| McCloskey | I44 |

| I54 | |

| Lippmann | 4248 |

| Gorgor | 1400 |

| 1200 | |

| Weeraryahan | 907 |

| 1112/1312 -100mm | |

| 1112/1312 -120mm | |

| 1315 | |

| Kumbee | No1 |

| No2 | |

| Shanghai Shanbao | PF-1010 |

| PF-1210 | |

| PF-1214 | |

| PF-1315 | |

| SBM/Henan Liming/Shanghai Zenith | PF-1010 |

| PF-1210 | |

| PF-1214 | |

| PF-1315 | |

| PFW-1214 | |

| PFW-1315 |